56283138 IR Motor 5 HP Air Compressor Electric Motor Capacitor Start/Run 24.9AMP

$429.99 USD

Related Categories:

Other Electric Motor

56283138 Motor 5 HP Air Compressor Electric Motor Capacitor Start / Run 24.9 AMP

Brand new, high starting torque design for compressor duty applications. Overload protection with manual reset. Steel frame and base. Welded base. Capacitor start/capacitor run.

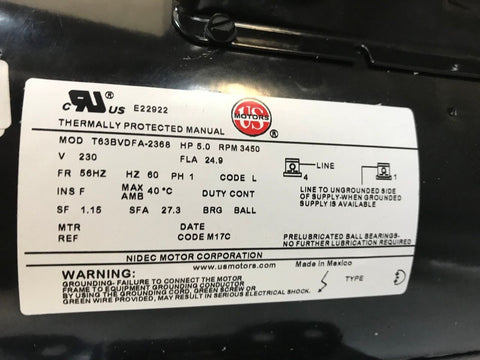

Confirm your motor name plate data tag including voltage, amperage, speed, frame and shaft diameter to match this motor specifications for proper operation.

SPECIFICATIONS

- Power 5 HP SPL

- FLA 24.9

- SFA 27.3

- RPM: 3450

- Frame: 184T

- Shaft Size: 7/8" x 2 1/4" with Keyway

- Shaft height: 4.5" (Measured to Shaft Center)

- Base: Flat Rigid Mounting Base

- Voltage: 208-230V 60hz, 24.9 AMPS

- Phase: Single Phase

- Service Factor: 1.15

- Insulation Class B

- Ball Bearings

- Open Drip Proof Enclosure

- Manual Overload Protection

1: Amperage .. This is your electric motors TRUE power rating. HP ratings have been made suspect over the years by large retailers who like to use "peak HP" or " SPL " in their terminology. The Motor's amp rating does not lie. Please make sure your FL amp (FULL LOAD) rating on the motor you're replacing is within 10% of the FL Amp rating of the motor you intend to buy.

Example 1: If your current motor says 21 FL amps at 230VAC. Then you would be safe replacing your motor with a 19FL amp thru 23 FL amp electric motor 230volt.

Example 2: If your current motor says 21 FL amps at 230VAC. Then you replace it with a 15 FL amp motor. That 15A motor is NOT strong enough for the task, and will eventually fail.

2: Frame Size .. The frame not only constitutes the overall size of the electric motor, it also depicts the bolt pattern to which you use to mount the motor. If your current motor you're replacing shows 56 Frame on the nameplate. Its extremely important that you replace it with a 56 frame motor. Improperly sized motors will inevitably result in motor failures.

Example: If your existing motor says 5HP 184T frame, and you elect to replace it with a 5HP 56frame.. That would be similar to putting a 4 cylinder engine in a school bus. It may work for a day, but it will eventually fail within the first hours of use. This is why its important that your new motors frame size matches the old motor you're replacing. This will ensure your replacement motor will work for years to come.

3: Phase and Voltage .. If your machine requires a 230volt electric motor on single phase power. You would want to incorporate a 1-phase 230vac electric motor for your application.

4: RPM .. Matching up the RPM is quite important. The wrong speed can damage your pump. The RPM does not have to match exactly, but you do need to be the neighborhood.

Example: 3510rpm, 3550, 3450 are all the same. They all fall under the umbrella of whats known as 3600RPM motors.

5: Shaft Diameter .. With a tape measure. Measure the outside diameter on your electric motors shaft. The most common 5HP compressor duty motor shaft diameters are 5/8" 7/8" 1 1/8"By matching up the proper shaft diameter, you will be able to reuse the original motor pulley that came on your machine. .

FREE STANDARD UPS SHIPPING FOR LOWER 48 STATES!